Choose Your Site

Global

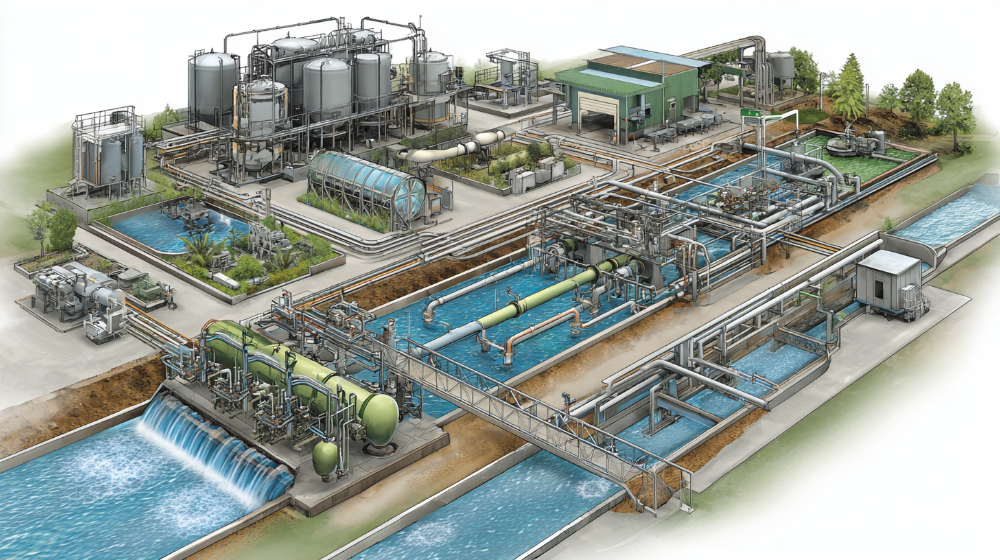

In the cycle of water resource management, wastewater treatment plants serve as essential "purification hubs." At the heart of the biological treatment process—the core of this purification—are aerobic microorganisms, the unsung army of workers responsible for breaking down pollutants. The effectiveness of these microscopic organisms hinges entirely on the supply of a single, critical resource: Oxygen.

While traditional aeration methods have been the standard for decades, they are increasingly revealing inherent inefficiencies that struggle to meet rising environmental standards and the constant pressure to reduce operational costs. Today, on-site oxygen generation technology is emerging as a game-changing solution, offering a more efficient, economical, and stable method to supercharge the biological treatment process. This article delves into how on-site oxygen generation is revolutionizing wastewater treatment by becoming the ultimate powerhouse for aerobic microbes.

In mainstream biological treatment processes like activated sludge and biofilm systems, we essentially "employ" billions of aerobic microbes to consume and break down organic pollutants.

Oxygen: The "Strategic Resource" Dictating Treatment Efficiency

Oxygen's role is comparable to "ammunition and fuel" for a modern army. It is the final electron acceptor in the oxidation of organic matter and the primary energy source for microbial growth and reproduction.

The Dissolved Oxygen (DO) concentration is the most critical operating parameter in a biological tank. When DO is maintained at an optimal 2-4 mg/L, the microbial community thrives, efficiently converting organic matter into CO₂, water, and new biomass.

An oxygen deficiency triggers a cascade of operational nightmares:

Plummeting Efficiency: Microbes become "lethargic," leading to effluent BOD/COD non-compliance.

Sludge Bulking: Filamentous bacteria, which thrive in low-oxygen conditions, can outcompete beneficial microbes, causing poor sludge settling and secondary pollution.

Odor Nuisance: The environment shifts from aerobic to anaerobic, prompting anaerobic bacteria to produce malodorous gases like H₂S and NH₃.

System Failure Risk: Under sudden high-load conditions ("shock loads"), a low-oxygen system is fragile and slow to recover, risking a complete biological treatment failure.

For years, wastewater plants have relied on traditional blower aeration, which forces ordinary air (only ~21% oxygen) into the water.

1.The Core Problem: Poor Oxygen Transfer Efficiency

Air is comprised of approximately 78% nitrogen, an "inert" gas in the biochemical reaction. Traditional aeration expends most of its electrical energy on heating and moving this useless nitrogen, with only a small fraction actually used to dissolve oxygen. The oxygen transfer efficiency (OTE) is typically a meager 5-15%.

To prevent microbes at the far end of the tank from suffocating, the inlet must be over-aerated, resulting in massive energy waste.

2.The Cost of "Inefficient" Operation

Exorbitant Energy Consumption: Aeration systems are the "energy hog" of a treatment plant, often accounting for 50-70% of the total facility's electricity bill. This is a significant and growing financial burden.

Poor Resilience to Shock Loads: When influent pollutant concentration spikes, traditional aeration cannot rapidly increase oxygen intensity due to its inherent transfer rate limits.

Large Footprint: Lower treatment efficiency often necessitates larger tank volumes to compensate, increasing capital and land costs.

3.On-Site Oxygen Generation: A Precision-Engineered Revolution

On-site oxygen generation, specifically Pressure Swing Adsorption (PSA) and Vacuum Swing Adsorption (VPSA) technologies, produces high-purity oxygen (90-95% concentration) directly from ambient air. This provides a perfect technical solution to the limitations of traditional aeration.

Core Technology: How Efficient, Low-Cost On-Site Oxygen is Made

PSA/VPSA Principle: These systems utilize a specialized zeolite molecular sieve that selectively adsorbs nitrogen from air under pressure. By cycling between pressurization (adsorption) and depressurization (desorption), they continuously produce a stream of high-purity oxygen. The process is normal temperature, fully automated, safe, and reliable.

A Simple Analogy: An oxygen generator acts as an "intelligent sieve," filtering out nitrogen and other gases from the air, delivering a pure, concentrated stream of oxygen directly to the aeration system.

4.The Disruptive Advantages of On-Site Oxygen Generation

Advantage 1: Dramatically Enhanced Oxygen Transfer & Treatment Capacity

Applying Henry's Law: The solubility of a gas in a liquid is proportional to its partial pressure. When oxygen purity increases from 21% to 90%, its partial pressure rises by approximately 4.3 times. This exponentially increases the oxygen saturation level and the mass transfer driving force (KLa).

The Result:

Supercharged Microbes: Aerobic microorganisms operate in an oxygen-rich environment, significantly boosting metabolic and reproduction rates. Treatment efficiency can improve by over 30%.

Increased Volumetric Load: The same tank volume can treat a higher pollutant load, effectively achieving plant expansion without construction.

Improved Sludge Quality: Ample oxygen suppresses filamentous bulking, leading to a better Sludge Volume Index (SVI).

Advantage 2: Significant Reduction in Energy and Operational Costs

Precision Energy Investment: Energy is used solely to produce and dissolve "effective" oxygen, eliminating the waste of pushing vast quantities of nitrogen.

The Data Speaks: Real-world cases show that VPSA oxygen generation paired with efficient fine-bubble diffusers can reduce energy consumption per kg of BOD removed by 20-40% compared to traditional aeration.

Optimal Life-Cycle Cost: While requiring capital investment, the savings on electricity typically lead to a payback period of 2-4 years. Long-term, it is far more cost-effective than continuing with high-energy blowers or expensive liquid oxygen (LOX) deliveries.

Advantage 3: Superior Operational Stability & Control Flexibility

Rapid Response, On-Demand Oxygen: On-site generators can be integrated with in-tank Dissolved Oxygen (DO) probes for full automation. The system adjusts oxygen production in real-time to maintain the perfect biological environment.

Powerful Shock Load Resistance: Even during influent spikes, the system can instantly deliver the required oxygen, ensuring microbial stability and consistently compliant effluent quality, thereby mitigating regulatory risks.

Advantage 4: Enhanced Safety & Reduced Footprint

Eliminates LOX Dependency: It removes the hazards and management costs associated with transporting and storing cryogenic liquid oxygen.

Compact & Efficient: The higher treatment efficiency may allow for a smaller biological tank footprint or enable existing tanks to achieve higher standards, a key benefit for land-constrained plant upgrades.

Successfully implementing an on-site oxygen system requires a scientific and methodical approach.

Feasibility Assessment: Do You Need It?

Data Diagnosis: Analyze your current influent quality (BOD/COD), effluent standards, aeration energy costs, and any plans for expansion or regulatory upgrades.

Demand Calculation: Precisely calculate your required oxygen mass flow rate (kg O₂/h) based on pollutant load. This is the foundation for sizing the generator.

Technology Selection: PSA or VPSA?

VPSA Generators: Best suited for medium to large-scale applications (typically > 500 Nm³/h). They offer lower energy consumption per unit of oxygen, making them the most economical choice for large municipal and industrial plants.

PSA Generators: Ideal for small to medium-scale needs. They are compact, offer flexible investment options, and have quick start-stop cycles, perfect for industrial sites or as a backup system.

System Integration: Achieving the "1+1>2" Effect.

To fully leverage high-purity oxygen, it must be paired with an efficient oxygen dissolution system (e.g., covered basin with fine bubble diffusers, deep shaft aeration). Professional engineering design and integration are paramount.

In an era of tightening environmental regulations and rising energy costs, the operation of wastewater treatment plants is shifting from "basic compliance" to "precision efficiency." On-site oxygen generation technology is a pivotal enabler of this transformation.

It is no longer just an "alternative" or a "luxury technology" but a proven, mature solution that simultaneously delivers "Reduced Costs, Increased Efficiency, Improved Quality, and Expanded Capacity." It empowers the army of aerobic microbes with unparalleled logistical support, unlocking their full treatment potential.

For the forward-thinking plant operator, investing in a tailored on-site oxygen system is not merely a fix for current bottlenecks. It is a strategic decision that lays a smart and solid foundation for stable operation, regulatory compliance, and cost control for the next decade and beyond.